DECA Thermoforming machines

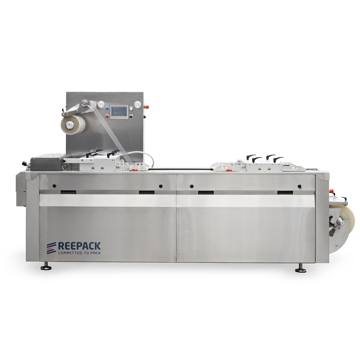

ReeForm E05

Compact thermoforming machine for small sized runs.

The machine is made of stainless steel to facilitate maintenance.

Max. width sub foil: 360 mm (420) mm

Speed: 4 to 8 cycles/minute. Suitable for vacuum and gas packaging.

The machine is made of stainless steel to facilitate maintenance.

Max. width sub foil: 360 mm (420) mm

Speed: 4 to 8 cycles/minute. Suitable for vacuum and gas packaging.

ReeForm E10

Compact thermoforming machine for small sized runs.

The machine is made of stainless steel to facilitate maintenance.

Max. width sub foil: 360 mm (420) mm

Speed: 4 to 8 cycles/minute. Suitable for vacuum and gas packaging.

The machine is made of stainless steel to facilitate maintenance.

Max. width sub foil: 360 mm (420) mm

Speed: 4 to 8 cycles/minute. Suitable for vacuum and gas packaging.

ReeForm E30

Compact thermoforming machine for small and medium sized runs.

The machine is made of stainless steel to facilitate maintenance.

Max. width sub foil: 360 mm (420) mm

Speed: 4 to 8 cycles/minute.

Suitable for vacuum and gas packaging.

The machine is made of stainless steel to facilitate maintenance.

Max. width sub foil: 360 mm (420) mm

Speed: 4 to 8 cycles/minute.

Suitable for vacuum and gas packaging.

ReeForm E40

Compact thermoformer made of stainless steel.

The stainless steel construction of both the basic chassis and the shields allow thorough cleaning.

The machine is suitable for processing flexible and semi-rigid film. The residual film is rolled up or discharged using a vacuum system.

Max. width of bottom film: 320 mm - 360 mm - 420 mm

Depth: max. 120 mm

Suited for vacuum/SKIN- and MAP packaging

The stainless steel construction of both the basic chassis and the shields allow thorough cleaning.

The machine is suitable for processing flexible and semi-rigid film. The residual film is rolled up or discharged using a vacuum system.

Max. width of bottom film: 320 mm - 360 mm - 420 mm

Depth: max. 120 mm

Suited for vacuum/SKIN- and MAP packaging

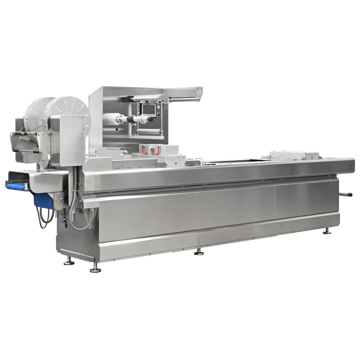

ReeForm T45

Modular thermoformer made of stainless steel.

This thermoformer can be customised to optimally meet your requirements. Length, width and film advance are determined based on your project specifications. The stainless steel construction of both the base and the chassis and the shields allows thorough cleaning.

The machine is suitable for processing flexible, semi-rigid or rigid film. The thermoformer tool and the cutting system are geared towards packaging materials. The residual film is rolled up or discharged using a vacuum system.

Max. width of bottom film: from 320 to 420 mm

Depth: max. 130 mm (optional 150 mm)

This thermoformer can be customised to optimally meet your requirements. Length, width and film advance are determined based on your project specifications. The stainless steel construction of both the base and the chassis and the shields allows thorough cleaning.

The machine is suitable for processing flexible, semi-rigid or rigid film. The thermoformer tool and the cutting system are geared towards packaging materials. The residual film is rolled up or discharged using a vacuum system.

Max. width of bottom film: from 320 to 420 mm

Depth: max. 130 mm (optional 150 mm)

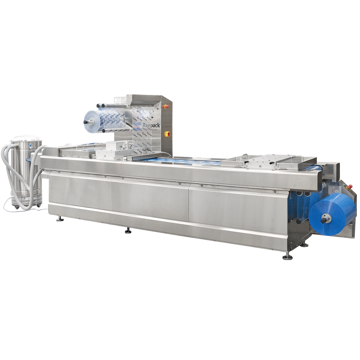

ReeForm T55

Modular thermoformer made of stainless steel with large tooling.

This thermoformer can be customised to optimally meet your requirements. Length, width and film advance are determined based on your project specifications. The stainless steel construction of both the base and the chassis and the shields allows thorough cleaning.

The machine is suitable for processing flexible, semi-rigid or rigid film. The thermoformer tool and the cutting system are geared towards packaging materials. The residual film is rolled up or discharged using a vacuum system.

Max. width of bottom film: from 440 to 560 mm

Depth: max. 130 mm (optional 150 mm)

This thermoformer can be customised to optimally meet your requirements. Length, width and film advance are determined based on your project specifications. The stainless steel construction of both the base and the chassis and the shields allows thorough cleaning.

The machine is suitable for processing flexible, semi-rigid or rigid film. The thermoformer tool and the cutting system are geared towards packaging materials. The residual film is rolled up or discharged using a vacuum system.

Max. width of bottom film: from 440 to 560 mm

Depth: max. 130 mm (optional 150 mm)